J2MG Nanocomposites

Pioneering the Future of Bio-engineering and Nanotechnology

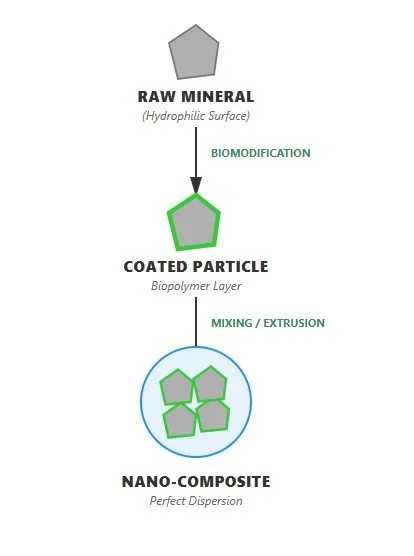

Mineral fillers featuring a nanostructured biopolymer coating that facilitates dispersion at the nanoscale.

What we do?

THE PROBLEM:

Limitations of Traditional Chemistry

High Cost: Traditional mineral modification (silanization) requires expensive, petrochemical-based reagents.

Sustainability: Chemical processes are energy-intensive and generate a significant carbon footprint, making "100% Eco" certification difficult.

Compatibility: The growing bioplastics market (PLA, PBAT) lacks dedicated, natural fillers that enhance mechanical properties without compromising sustainability.

THE SOLUTION:

Surface Biomodification

We have developed a scalable, solid-state surface bio-engineering process. Instead of synthetic coupling agents, we utilize natural biopolymer self-assembly processes.

How does it work? The technology involves generating an ultrathin, amphiphilic biopolymer layer directly on the mineral surface. This layer acts as a "molecular bridge" between the hydrophilic mineral and the hydrophobic polymer matrix.

"Mineral fillers featuring a nanostructured biopolymer coating that facilitates dispersion at the nanoscale."

J2MG Nanocomposites

Pillar I

From "Filler" to "Reinforcement"

We are reversing the market logic. Thanks to our biomodification, the mineral is no longer a foreign body within the polymer matrix. It becomes an integral, functional component. We don't just want to "fill" materials – we aim to enhance them at the molecular level.

Pillar II

From "Synthesis" to "Symbiosis"

The 21st-century chemical industry must draw inspiration from nature. Our production process mimics natural self-assembly mechanisms, eliminating the need for harsh solvents and high temperatures. We are building technology that is safe for both people and the planet.